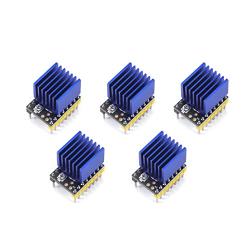

BIGTREETECH S42B V2.0 Closed Loop Driver Control Board 42 Stepper Motor with OLED Display Prevent Multi-Step and Losing Steps with Low Heat Generation for 3D Printer SKR V1.3/1.4 Board

Availability: Pre-Order, Inquiry Price

About this product

*❤【High operating efficiency】Compared with ordinary drives, this motor runs more Stably.Low calorific value, high operating efficiency.And it can print at high speed without losing step.

*❤【With OLED】With OLED, the current and subdivision of the motor can be modified by pressing the buttons, and displayed on the OLED to realize the visualization of human-computer interaction, and the operation is simple and convenient.

*❤【low noise and LOW vibration】Software algorithm to achieve low noise and low vibration.

*❤【Easy for secondary development and loading】C language development, easy to secondary development.Setting parameters can be saved to facilitate secondary loading.

*❤【New upgrade with CAN interface】Compared with S42B V1.0, the upgraded S42B V2.0 has a CAN interface.

Description

??24 MONTHS LONGER WARRANTY?We will provide a long-term warranty service of up to 24 months.If there is a problem with the product, please contact me before evaluating the product. I will try my best to help you (including full refund, return exchange).

?NOTES?

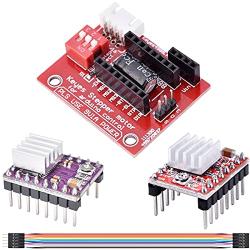

Only suitable for motherboards with socket stepper driver installation(For Example, SKR E3 DIP,SKR V1.4,SKR V1.4 Turbo and so on) Can not suitable for integrated driver motherboards(For Example, SKR mini E3)

S42B V2.0 Closed Loop Driver Control Board Specification?

Motor power supply (VM): 12V---24V

Default working current of the motor: 800mA

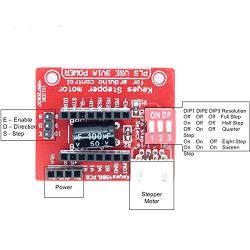

Drive subdivision default: 16 subdivision

Subdivision number: 2 4 8 16 32

Maximum current: 1650mA

Maximum speed: 1000RPM

Main control chip: STM32f103cbt6, Crotex-M3, clocked at 72MHz

?ATTENTION?

1 ?When inserting the adapter board, please pay attention to the direction of the adapter board. Notice the motor and the loop chain wiring sequence!

2?For the first time, the closed-loop driver board must be connected to the motherboard with firmware, and then the encoder shall be calibrated. The calibration time will take 1-2 minutes

3?Check if the driver is installed when connecting to the computer with the serial port.

4?When the data displayed on the display or serial port is abnormal, please remove the closed-loop driver board and check if the magnet on the motor shaft is in the center position. If not, please return it to the center for recalibration.

5 ?After completing the calibration, do not set it immediately after power-on. Please wait for the initialization to complete (1-2s) before setting the parameters.

6?Please do not manually turn the motor after power on.

7?The distance between the magnet at the center of the motor shaft and the core encoder should be greater than 2mm.

8 ?Full stability of machine structure must be guaranteed