V TELESKY TB6600 Stepper Motor Driver Nema 23 Stepper Motor Driver for Nema 17, 23 Series Stepper Motor CNC Controller Single Axis Hybrid MicroStepping(1 pcs)

About this product

*【Product name】TB6600 Stepper Motor Driver

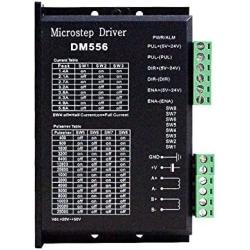

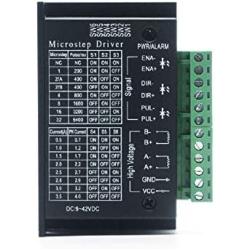

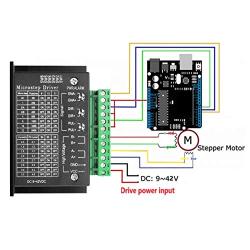

*【Parameter】:Driver model:TB6600; input voltage:DC9~42V;Current:4A; Fine fraction:6400

*【Various protection】: over-current protection, over-voltage protection, under-voltage protection, short-circuit protection, off-line (ENA) protection function

*【Application】Suitable for any small-and-medium automatic equipment with CNC controller, such as X-Y-Z tables, labeling machines, laser cutters, engraving machines, and pick-place devices

*【Package included】1 X Stepper Motor Driver For Arduino

Description

Failure relative to the problem and the solution measures.

1? Alarm light on

2, the motor does not turn, and no holding torque

3, the motor does not rotate, and there is a holding torque

4?The motor rotation direction is wrong

5, the motor torque is too small

6, the position is not allowed

7, motor acceleration blockage

motor connected to the wrong line, check and connect the linevoltage is too large or too small, check the power supplymotor connection is not correct, correct the motor connectionoffline to enable RESET signal, valid, make RESET invalidno pulse signal input, adjust the pulse width and the level of the signalsubdivision is too small, the correct choice of subdivisioncurrent setting is too small, the correct choice of subdivisiondrive has been protected, re-power after power failurepower line phase sequence is connected to the wrong, interchange any two connected lines (for example) A +, A- swap connectedmotor line has a break, re-check and connected correctlydirection signal input is not correct, change the direction settingphase current setting is too small, set the correct phase currentacceleration is too fast, city small acceleration valuemotor blocking, eliminate mechanical problemsdrive and motor do not match, change the appropriate drivesignal interference, eliminate interferencesubdivision is not correct, set the correct subdivisioncurrent is too small, increase the currentmotor line connection is not good, check and connect the rightacceleration time is too short, lengthen the drying timemotor torque is too small, choose the right torque motorvoltage or current is too low, increase the voltage or adjust the current