Description

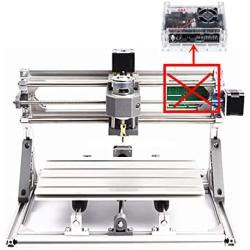

1 x 3 Axis 3018 Pro Max GRBL CNC Router Engraving Machine Kit 1 x 775 spindle motorw/ ER11 Collet10 x 20°0.1mm drill bits1 x GRBL 1.1F Control Board1 x Offline hand controller1 x Set of allen wrench4x Plate clamps1 x Power Supply1 x 4G USB flash drive include english user manual and GRBL softwareConnection: PC-USB connection

Support software: GRBL controller/Candle/UniversalGcodeSender

Input voltage: 12-24VDC

Master chip: atmel 328P (arduino nano)

Spindle drive chip: MOSFET (recommendation 24V, current : within 10A

Spindle PWM speed: Support

Support stepper motor: 12V, maximum current of 2A or less is recommended within 1.5A and additional heat. (Any stepper motor Nema17/Nema23)

Power Interface: 5.5-2.5mm DC interface

Support 3-pins module: supportSupport SD card and TF card at the same time, standard capacity 1G.With this offline controller module, you can directly control the CNC router without connecting it to your computer.After inserting the file into the SD card,the engraving file can be directly identified. You can also use the micro USB cable to connect the offline hand controller board to your computer and save the file directly.Manually control: manually adjust X,Y,Z axis location as engraving starting point,manually open or close spindle,manully open or close cooling fanFile engraving: after off-line controller save file, it can connect the GRBL control board and process engraving,no need to connect PC computerSave file: after the off-line controller connect PC,it will be recognized as USB,large capacity storage device, can access engraving file directly.SD shows it is SD card condition,turn on power supply after insert SD card,otherwise,it wont work.SD card capacity 4G could be recognized.

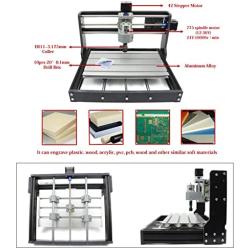

Spindle parameters: 775 spindle motor (12-36V) 24V:10000r/min

Mounting hole diameter: M4 screw hole; Mounting hole pitch: about 29mm.

Spindle PWM speed: Support;power 0-100% adjustable

Motor shaft diameter: 15mm; Motor diameter

Drill clamp parameters: ER11-3.175mm ( can be replaced 0-7mm )

Control software: grbl control(candle)

Spindle Chuck: ER11

Processing accuracy: About 0.2mm

Machinable material: Wood? plastic? PCB? PVC? carbon fiber? acrylic? density board etc

Power: DC 24V 5.6A power adapter (input voltage 110-240VAC)

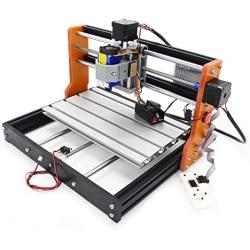

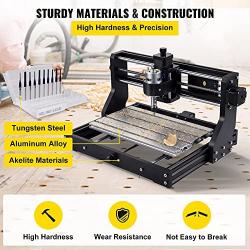

Support oftware: GRBL controller,Candle, UniversalGcodeSenderAdd emergency stop button port,tool probe port and XYZ limit port.Input voltage: 12-24VDCThe spindle supports 0-100% adjustable PWM power.Support limit switch, tool setting, steering gear, cooling fan and other functions.Support PWM / TTL signal control, power 0-100% adjustable!Increase the power button switchCancel the drive module,integrate the imported stepper motor drive, and comes with short circuit protection, no need to worry about module damage. And integrated heat dissipation aluminum alloy.Add offline recognition function, you can insert offline module and computer at the same time. The machine will automatically recognize whether it is controlled by the computer.Enhanced spindle drive.can support 20,000 rpm spindle.Add the fan port to force heat dissipationCNC 3018 Pro Max Mini CNC machine small size, light weight, USB interface, GRBL control systems, great cnc router machine for beginers;3018 Rro Max cnc machine is very easy to install,stable structure.Main application:can be engraved plastic, wood, acrylic, pvc, pcb, wood and the like material.soft metal like copper and aluminum and other materials, but can not carve hard metal, jade or other very hard texture of the items.if you change the spindle to a 3pins module,also can carve the kraft paper, wood, leather(wallet), bamboo.Working area: 30x18x4.5cm(approx.11.81x7.08x1.77 inches)Frame size :42x35x27cm(approximately 16.53x13.78x10.63 inches)Processing thickness:4.5cm (height 6.4cm)Material: Aluminum Alloy;Screw rod: T8 screw rod, lead 4mm, double copper nut backlashStep motor: nema17 stepper motor 42x42x34mm,1.3A,0.25N.mPower supply : 24V 5.6A power adapter (input voltage 110-240V)Support System:Windows XP / Win 7 / Win 8 / Win 10. Linux;Supporting file:G-code (.nc/.txt/.tape/.gcode)Processing accuracy:About 0.2mmControl system:grbl control, USB interfaceCtrl: Machine Control; File: Use the Gcode file; Press [Y+] [Y-] to select; Press[Ok] to EnterX± Y± Z±: Moving AxisOK/Spindle: Spindle ON/OFFExit/Step: Change Step/Exit (long press)How to increase the spindle power: After pressing the spindle button, press and hold the OK button and the Z+ button simultaneously to increase the speed.How to decrease the spindle: After pressing the spindle button, press and hold the OK button and the Z- button simultaneously to decrease the speed.Common supported formats include nc. tex. tap.Press [Y+] [Y-] to select filePress [Ok] to EnterPress [Ok] to begin if you are readyNote:Long press [Exit] to stop machiningOur parcel include a 4G USB flash drive,you can download the english user manual and GRBL software from the flash drive.File Format (gcode): *.nc, *.ncc, *.ngc, *.tap, *.cnc.Software used to create Gcode: Carbide Create, Artcam, MeshCam, Fusion360, Inkscape etc.