Gear Motor High Torsion Metal , Gowns Surgical Gowns Wheel Micro Synchronous Motor Eccentric Output Shaft Micro Speed Reduction Machinery for Micro Machinery

Availability: Pre-Order, Inquiry Price

About this product

*Product Usage. The use of gear motors can only reduce the motor speed, not increase the speed. Gear motors are characterized by low noise and high torque.

*Metal Gear Protection Function. The gear motor adopts all-metal gears with high temperature resistance, high wear resistance, sturdiness, and strong load-bearing capacity, which effectively protects the gearbox motor body.

*Powerful. The gear motor adopts precision winding pure copper wire technology, and the power of the geared motor is instantly increased by 30%.

*Shock Resistant. The geared motor is made of high-hardness steel, which has good toughness and impact resistance.

*Long Lasting. The gear motor improves the bearing quality and the service life of the geared motor, which increases the service life.

Description

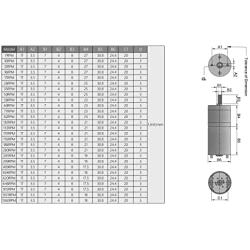

Specification:

Bearing Type: Oil Bearing

Gear Material: Metal

Motor Wire Material: Copper Wire

Spindle Material: Steel

Radial Force: ?1 kgf

Axial Force: ? 0.7 kgf

Maximum Bearing Capacity of Spindle: ? 5 kgf

Rated Voltage: DC 12V

ZGB37RG 1000R-12V:

Reduction Ratio: 1:3

Load Speed: 1000RPM

Load Speed: 700RPM

Load Torsion: 0.1kgf.cm

Gear Box Size: 37 x 23mm (1.4in x 0.9in) (D L) (Manual Measurement Error ±1mm)

Output Shaft Size: 6 x 14mm (0.2in x 0.5in) (D L) (Manual Measurement Error ±1mm)

Motor Size: 36.0 x 33.3mm (1.4in x 1.3in) (D L) (Manual Measurement Error ±1mm)

Mounting Hole Size: M3

Uses: Automatic Vending Equipment, Panning Cameras, Slot Machines, Currency Detectors, Coin Return Equipment, Automatic Doors, Peritoneal Machines, Toy Motors, Etc.

Package List:

1 x Motor

Note:

1. Use tolerance: pay attention to the use of voltage and current range, otherwise the performance and life of the motor will be reduced.

2. Transport the motor: gently, try to use a part of the motor housing.

3. Motor wiring: red leads to the positive pole, black leads to the negative pole, if the connection is reversed, the motor rotates in the reverse direction.

4. Overload: As far as possible within the specified load range, it is forbidden to run the motor for too long in a locked?rotor or close to stall state. Otherwise, the motor will burn out.

5. Motor storage:

?Storage temperature: 0??40?;

?Storage humidity: 15%?90%RH;

?Avoid placing in high temperature, high humidity and corrosive gas.

6. Motor operating temperature: 0??70?