DC 24V Gear Motor Shaft 37mm Diameter Electric Gearbox Micro Speed Reduction Geared Motor(160R)

About this product

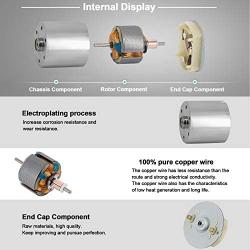

*Has high temperature resistance, high wear resistance, strong bearing capacity, durable and effective protection of electric body. Adopting precise winding pure copper wire technology, the power of reducer motor is increased by 30% instantly.

*Adopts high hardness steel, good toughness, impact resistance, bearing quality and gear motor service life is improved, very durable. Can adjust the speed, but only reduce the motor speed, not increase the speed. Low noise and high torsion.

*Suitable for vending equipment, cash detector, coin return equipment, automatic door, peritoneum machine, toy motor, etc.

*Type of Bearing: Oil Bearing; Gear Material: Metal; Material Of Motor Wire: Copper wire; Spindle Material: Steel; Radial Force: ≤ 1 KGF; Axle Force: ≤ 0.7kgf; Maximum Bearing Force of Spindle: ≤ 5 KGF; Rated Voltage: DC 24V

*Output Shaft Size: Approx. 6 x 14mm / 0.2 x 0.6in(manual measurement error ±1mm); Motor Size: Approx. 36 x 33.3mm / 1.4 x 1.3in(manual measurement error ±1mm); Mounting Hole Size: M3; Uses: Vending equipment, cash detector, coin return equipment, automatic door, peritoneum machine, toy motor, etc

Description

ZGB37RG 570R?24V:

Reduction Ratio: 1:8.7

Load Speed: 570RPM

Load RPM: 420RPM

Load Moment: 0.3kgf.cm

Transmission Size: Approx. 37 x 23mm / 1.5 x 0.9in (manual measurement error ±1mm)

ZGB37RG 285R?24V:

Reduction Ratio: 1:17.4

Load Speed: 285RPM

Load RPM: 210RPM

Load Moment: 0.7kgf.cm

Transmission Size: Approx. 37 x 23mm / 1.5 x 0.9in (manual measurement error ±1mm)

ZGB37RG 160R?24V:

Reduction Ratio: 1:31

Load Speed: 160RPM

Load RPM: 135RPM

Load Moment: 1.15kgf.cm

Transmission Size: Approx. 37 x 25mm / 1.5 x 1in (manual measurement error ±1mm)

ZGB37RG 33R?24V:

Reduction Ratio: 1:148

Load Speed: 33RPM

Load RPM: 28RPM

Load Moment: 5.3kgf.cm

Transmission Size: Approx. 37 x 29.5mm / 1.5 x 1.2in(manual measurement error ±1mm)

Note:

1. Use tolerance: pay attention to the use of voltage and current range, otherwise the motor performance and life will decline.

2. Handle the motor: Gently, try to use part of the motor housing.

3. Motor wiring: red leads to the positive pole, black leads to the negative pole, if the connection is reversed, the motor will reverse rotation.

4. Overload: as far as possible within the specified load range, it is forbidden for the motor to run for too long in locked?rotation or near stall state.Otherwise, the motor will burn down.

5. Motor storage:

? Storage temperature: 0??40?;

? Storage humidity: 15%?90% RH;

6. Motor operating temperature: 0??70?

![DC 24V Gear Motor Shaft 37mm , Learning & Education Science Kits & Toys Diameter Electric Gearbox Micro Speed Reduction Geared Motor[570R]](https://www.motormaker.net/image/cache/catalog/img/41h/41hsezyVlOS-250x250.jpg)

![DC 24V Gear Motor Shaft 37mm , Learning & Education Science Kits & Toys Diameter Electric Gearbox Micro Speed Reduction Geared Motor[570R]](https://www.motormaker.net/image/cache/catalog/img/31R/31RdshuKqBS-250x250.jpg)

![DC 24V Gear Motor Shaft 37mm , Learning & Education Science Kits & Toys Diameter Electric Gearbox Micro Speed Reduction Geared Motor[33R]](https://www.motormaker.net/image/cache/catalog/img/31U/31U1aPAz+yS._AC_-250x250w.jpg)

![DC 24V Gear Motor Shaft 37mm , Learning & Education Science Kits & Toys Diameter Electric Gearbox Micro Speed Reduction Geared Motor[33R]](https://www.motormaker.net/image/cache/catalog/img/31m/31m9eyhLXWS._AC_-250x250h.jpg)