RTELLIGENT RS485 Modbus/RTU Protocol Stepper Driver 2 Phase 5A 24-50V Digital Control Nema 23/24 for 3C Equipment/CNC Machine (NT60)

About this product

*Modbus stepper driver: 24 ~ 50V DC power supply, 5.0A output current peak. Support offline. Size: 118 * 75.5 * 33mm (4.65 * 2.97 * 1.30 inches)

*With the built-in S motion profile acceleration and deceleration can be set separately.

*Low Noise: Based on advanced control algorithm, the motor driver can run with low noise and low vibration

*Application: This NT60 stepper motor driver can control almost all of 2 phase nema 23/24 stepper motors 57/60mm flange whose current is under 5.0A. Usually for production line, Li-on battery equipment, solar energy equipment, 3C electrical equipment, etc.

*Warranty: Our step driver CNC controller has 12 months warranty. CE, ISO Certificated

Description

Shenzhen Rtelligent Mechanical and Electrical Technology Co., Ltd is a manufacturer which has full motion controlling products including motion controller, stepper servo drive, stepper servo motor, stepper drive and stepper motor with well-equipped testing facilities and strong technical power.

Shenzhen Rtelligent Mechanical and Electrical Technology Co., Ltd is a manufacturer which has full motion controlling products including motion controller, stepper servo drive, stepper servo motor, stepper drive and stepper motor with well-equipped testing facilities and strong technical power.Rtelligent NT60 is a MODBUS / RTU stepper motor with RS485 communication suitable for 4-wire 2-phase Nema 23/24 stepper motors with a flange of 57/60 mm and currents less than 5.0A.

Rtelligent NT60 is a MODBUS / RTU stepper motor with RS485 communication suitable for 4-wire 2-phase Nema 23/24 stepper motors with a flange of 57/60 mm and currents less than 5.0A.

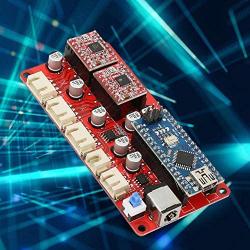

Connection

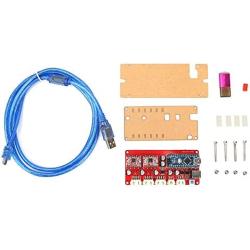

Package Contents:

1 x NT60 RS485 Modbus/RTU Protocol Stepper Driver

Slave address setting: Baud rate setting: Cn interface: Encoder interface: RJ45 interface: Power and Motor interface: Indicator SW1-SW5,the five DIP switches, are used to set 32-bit DSP addresses in total. Please select the corresponding position according to the drive panel. SW6-SW7, the two DIP switches, are used to select a total of 4 baud rates in total. The master and slave must be set to the same baud rate. Please selectthe corresponding position according to the drive panel.Terminal matching resistor:sw8 is used to select whether the 120 ohm terminating resistor is valid, off is invalid, and on is valid. 4 single input port, 2 output port. GND : Internal power supply output GND; +5 V : Internal power supply output 5V. When operating in the closed-loop mode, 5V power is supplied to the encoder. The maximum output current of this 5v signal should not exceed 150mA.IN2-, IN2+ : The differential input signal, the 5v level signal, can receive the pulse signal when the external pulse is open loop, and the quadrature encoder A phase signal in the closed loop mode. IN1-, IN1+ : Receives the quadrature encoder B-phase signal as the IN2 port. Network communication interface, also used to connect PC debugging software. V-, V+ is powered by DC power supply. 24 - 50V DC is recommended for the operating voltage range, the power supply is greater than 150W. A+, A-, B-, and B+ are respectively connected to the A and B phase windings of the two-phase motor.: The drive has two indicators: the green one, a power indicator and twinkle upon the power up of drive; the red one, a fault indicator and twinkle in case of overvoltage and overcurrent. The red indicator goes off only when the fault is removed. The fault of drive can only be removed when the drive is powered on and enabled again.