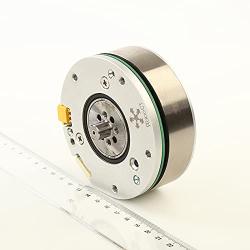

400rpm Pneumatic Motor for Pneumatic Tapping Machine M3-M12 with diameter 38mm

Availability: Pre-Order, Inquiry Price

About this product

*Speed: 400 RPM, Tapping capacity: M3-M12

*Motor size: 38mm

*Working presure:0.7MPA M12 need to work pressure: 0.7-0.8MPA stable pressure

*Note: Do not use a high viscosity oil or grease instead, that would cause the tool rotation is not normal or even damaged. 3Parts of pneumatic tools is a piece of precision machining, so throwing, dropping or rough handling is strictly prohibited.

*Note:Before using the tool, please read through the operating instructions to ensure safe use

Description

I. Description

1Before using the tool, please read through the operating instructions to ensure safe use.

2Pneumatic tools should normally be5-7Work under pressure kg. In operation, the gas consumption tool should be as shown in the specification tool. However, at the same time when many of the tools used air compressor assigned to the tool needs more than the total amount of gas consumption. In general, the amount allocated to the instrument air should be more than the total gas consumption20%About.

3Before using inspection tools without exception, pressure is normal, the tube is wound.

4, It is forbidden to change the structure and design of tools and accessories.

5When operating the tool, repair tools or change parts, please feel free to put on blinders and impact resistant mask (face protection equipment). And does not work, please turn off the air supply and disconnect the connector tools and air supply.

6, Set the rotating shaft and accessories keep their distance, do not wear jewelry and empty fat suit to use the tool, a good bundle hair, scarves, ties and other material easy to wound.

7When the operation, equipped with good labor protection devices and clothing.

8, Operation, please keep the body in a balanced position foothold and safety.

9Do not be the outlet at yourself or others.

Second, maintenance

1Supply tools gas source to be treated to ensure clean and dry.

2Please use the oiler to lubricate the tool and adjust the flow rate per minute3-4Drops, without using the oiler, you need every day from the oil filling pipe joints3-4Drops. Please use the company-specific lubricating oil, the oil injection, please idle in order to facilitate the discharge of oil and use part of the lubricating oil with a portion of the impurities.